Written by: Sam Green - Water Treatment Engineer - Technical Services

I was recently called out to a site where the water softener had stopped using salt.

My first step in any softener fault-finding job is always to check for hardness to see if the softener is passing hard water. In a duplex or multiplex system, I’ll switch the vessel in service and retest. On this occasion, the water was 100% soft — no immediate issue there.

So then, why wasn’t it consuming salt?

One possibility was an intermittent issue, such as a blockage that had cleared itself. But the real cause wasn’t the softener at all — it was the brine tank. A bit of salty digging revealed a solid crust of salt inside: salt bridging.

What Is Salt Bridging?

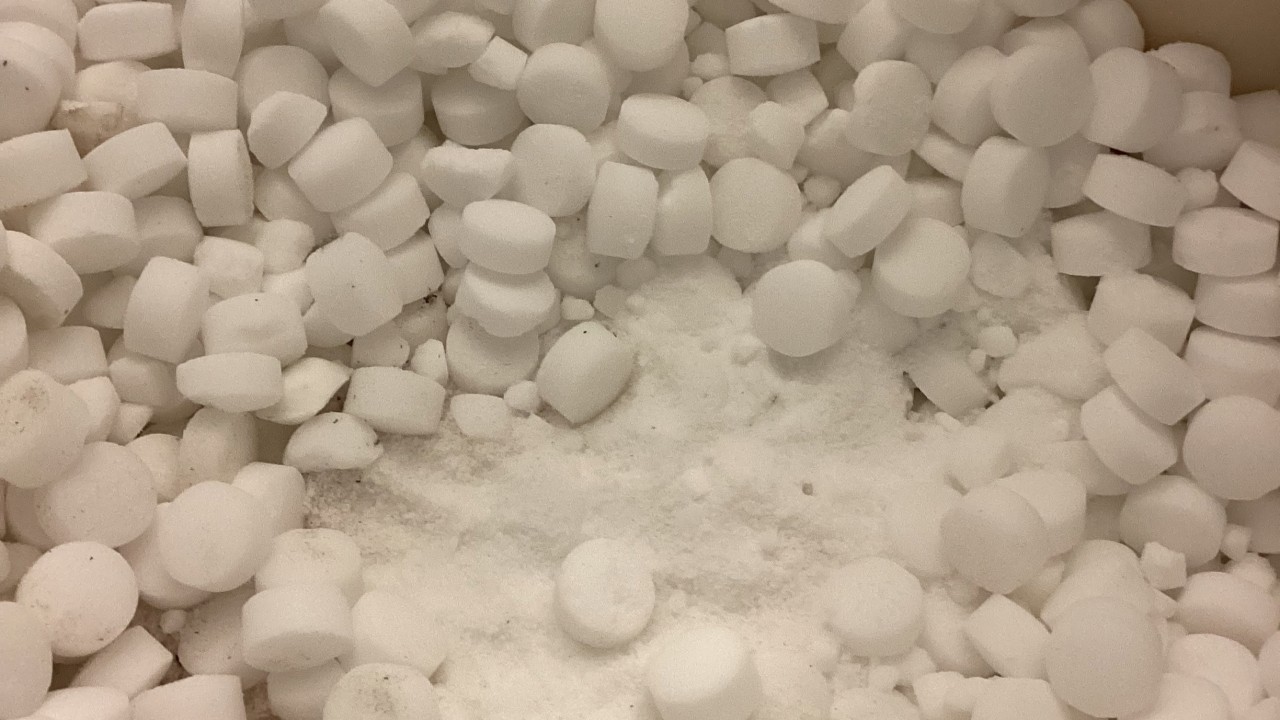

Salt bridging occurs when salt in the brine tank forms a hard crust or “bridge” above the water level. The salt below the bridge dissolves and gets used during regeneration, leaving a layered tank like a salty trifle — water at the bottom, an air gap in the middle, and a deceptive layer of salt sitting above the bridge.

From the top, it looks like the tank is full of salt, but in reality, a hollow sits below. As the brine becomes weaker, regeneration becomes less effective because the weakening brine can no longer effectively drive the exchange of calcium and magnesium ions for sodium on the resin beads. Eventually, the softener ends up regenerating with plain water — and stops producing soft water altogether.

What Causes It?

Common causes of salt bridging include:

- High humidity

- Temperature fluctuations

- Using the wrong type of salt

- Infrequent regeneration

- And in this case — overfilling the brine tank

This client was very diligent about keeping the tank topped up to the brim — which, while better than forgetting to add salt at all, likely led to the problem. When the salt level is constantly kept at maximum, the weight compacts the lower layers, making bridging much more likely.

The Fix

Fortunately, the solution is simple: break up the salt bridge with a broom handle or similar tool. In this case, once the bridge was broken, the salt dropped around six inches as it filled the hollow space below.

The client’s regular checks meant the issue was caught early — before hard water was ever passed through the system. A great example of attentive maintenance paying off.

Key Takeaway

Keep the salt level in your brine tank just above the water level. This ensures full contact between salt and water for proper brine formation — without putting excess weight on the lower layers. Every so often, check for a bridge in the salt with a broom handle. And depending on your setup, it’s a good idea to let the salt run down occasionally so you can give the brine tank a proper clean-out.